Real Thrust, Real Insight■

In naval propulsion, precision equals endurance. TT-Sense® gives navies direct visibility into actual thrust and torque, revealing how power is truly converted into movement.

By separating propeller efficiency from hull resistance, TT-Sense® enables crews to optimise trim, detect fouling, and cut fuel use by up to 20%.

Its optical, non-contact design ensures maintenance-free reliability and long-term stability, even under shock, vibration, or electromagnetic interference.

Fully type-approved and ready for integration with PEM4, SPU3, and IVY®, TT-Sense® turns propulsion data into actionable insight, supporting mission planning, efficiency management, and compliance with naval standards.

True Propulsion Insight

Measure real thrust and torque for a complete view of propulsion performance.

Maintenance-free Reliability

Non-contact optical sensing ensures continuous operation with zero wear or recalibration.

Optimised Efficiency

Separate propeller and hull performance to cut fuel and maintenance costs.

Operational Advantage

Detect fouling, optimise trim, and maintain peak efficiency across every mission.

We present:

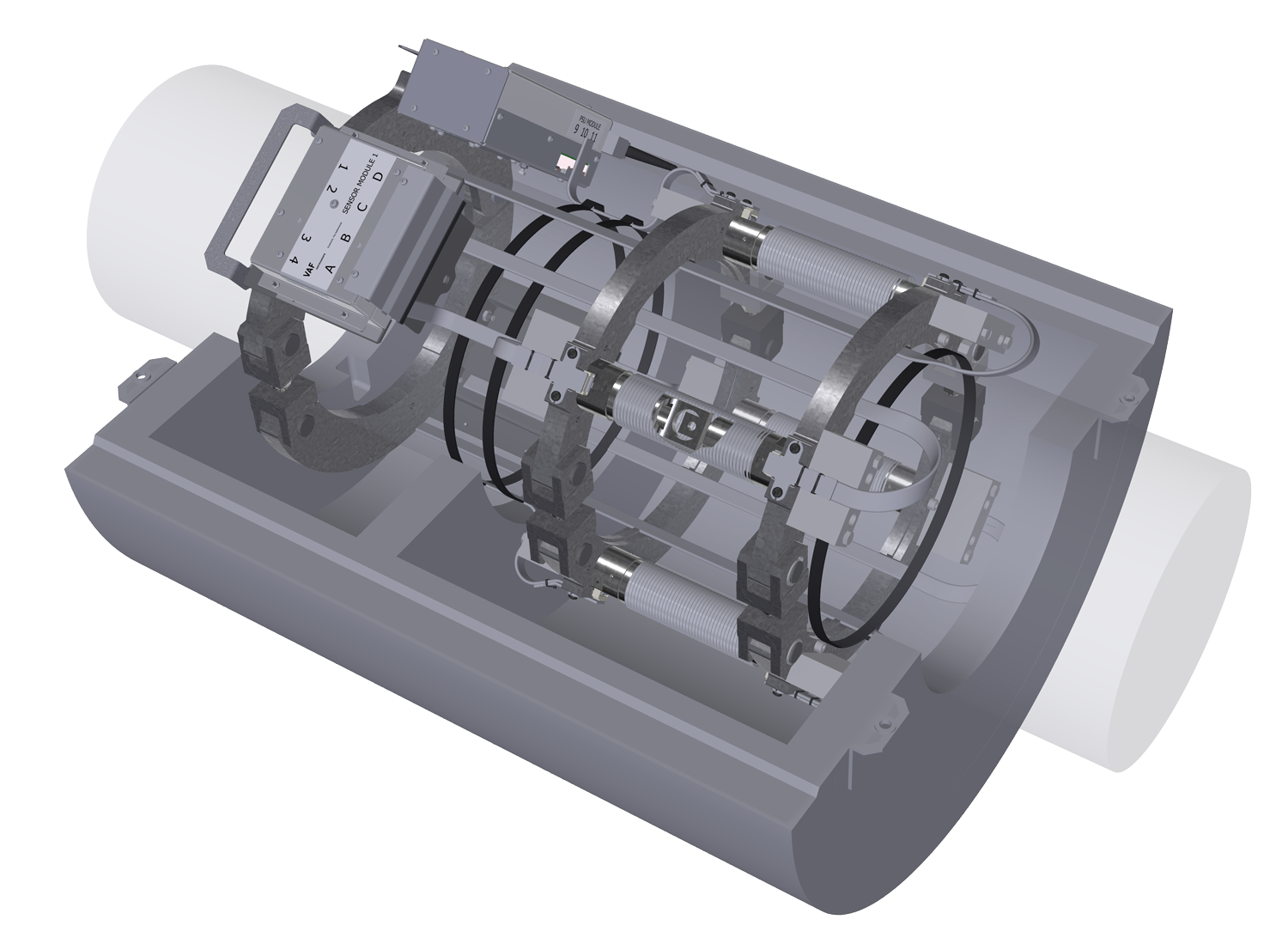

TT-Sense® NG■

TT-Sense® is VAF’s optical thrust & torque measuring system, purpose-built for naval propulsion control. Mounted on the intermediate shaft, it continuously measures both axial thrust and torsional torque, delivering real data on how power is transformed into forward motion. This insight enables precise trim optimization, hull-fouling detection, and performance benchmarking, essential for reducing resistance, extending range, and maintaining mission readiness.

Key features:

- Measure micro-strain in both axial (thrust) and radial (torque) directions for full propulsion insight

- ≤ 0.25 % F.S.D. torque, ≤ 1 % F.S.D. thrust, guaranteed over the entire load range

- Inductive power and encrypted 2.4 GHz data transfer ensure zero wear and secure signal integrity

- Robust, sealed housing resists vibration, shock, salt spray, and electromagnetic interference

- Suitable for shafts 200 mm – 1000 mm in diameter across all propulsion types

- Outputs via Modbus, Ethernet, or 4-20 mA; plug-and-play with PEM4, SPU3, IVY®, and AMS

- Maintenance-free, no recalibration, designed for continuous operation in mission environments

- Type-approved by leading classification societies and compliant with naval quality frameworks

Ensure Low Operating Costs

- Identifies propulsion inefficiencies early, preventing unnecessary fuel burn

- Enables accurate trim and hull resistance optimization

- Reduces maintenance by detecting load imbalance and stress

- Maintenance-free optical system eliminates servicing and recalibration costs

Easy to install

- Compact, modular housing fits directly on the intermediate shaft

- Split-ring design allows installation without shaft removal

- Plug-and-play connectivity via Modbus or Ethernet

- No alignment or field calibration required

Quality & Durability

- Sealed, corrosion-resistant construction ensures long service life

- Proven accuracy under variable loads and sea states

- Optical sensors maintain calibration for the full lifecycle

- Type-approved by major classification societies

Unique Product Features

- Simultaneous thrust and torque measurement for real-time performance tracking

- Seamless integration with PEM4, IVY®, and AMS systems

- Secure 2.4 GHz wireless transmission for interference-free data

- Fully compliant with naval quality assurance and traceability frameworks

TT-Sense® Delivering measurable propulsion assurance for every mission.

Our experts are

standing by■

Our naval specialists stand ready to support your fleet in enhancing propulsion efficiency, compliance, and mission readiness.

Erik van Ballegooijen | R&D Director